When Your AC Fan Stops But Compressor Keeps Running

Have you ever felt warm air blowing from your vents even though your AC is running? If your fan turns off but compressor stays on, you’re facing a specific AC malfunction that needs prompt attention.

I’m Courtney Zalesak, Vice President at Malek Service Company. After helping homeowners solve HVAC problems for over a decade, I can tell you this issue is both common and potentially serious for your system.

When your outdoor unit hums along but doesn’t cool your home, it’s usually because the fan has stopped while the compressor continues working. This creates a double problem: your home stays uncomfortable, and your AC system could suffer expensive damage.

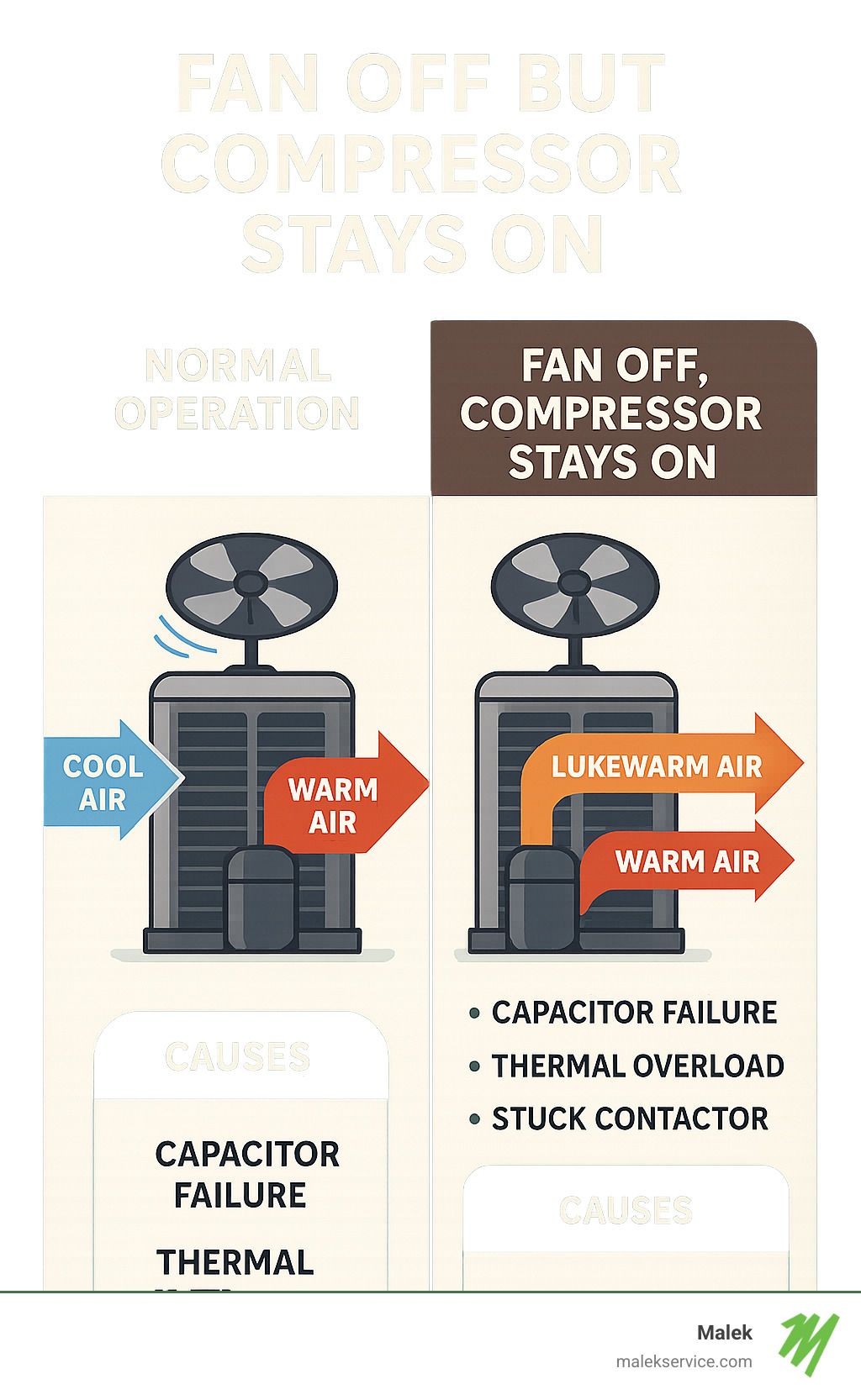

Here’s what’s likely happening when your fan turns off but compressor stays on:

Thermal overload protection might be triggering your fan motor to shut down temporarily when it gets too hot. The motor has a built-in safety switch that cuts power when temperatures rise too high, protecting it from burning out completely.

A failed capacitor is another common culprit. Think of the capacitor as your fan motor’s battery boost – when it fails, your fan can’t get enough starting power even though the compressor (which might use a different capacitor) keeps running.

Sometimes a stuck contactor (the electrical relay that controls power to your components) can malfunction, sending power to your compressor while the fan circuit fails.

Dirty condenser coils force your system to work harder and run hotter, often triggering that thermal shutdown in the fan motor while the compressor soldiers on.

Occasionally, a faulty control board might be sending power signals to your compressor but not your fan, creating this imbalanced operation.

Your air conditioner’s compressor acts like a heart, pumping refrigerant through the system to absorb heat from your home. But without the fan moving air across the coils, that heat transfer process breaks down. The result? A hot house, wasted energy, and potentially serious damage to your expensive compressor.

This isn’t just about comfort – when your fan turns off but compressor stays on, your system is essentially running blind, unable to properly manage the heat it’s trying to remove from your home. The longer this continues, the greater risk of serious damage to your system’s most expensive components.

In the following sections, we’ll explore exactly why this happens and what you can safely check yourself before calling in the professionals. After all, sometimes the fix is simple enough for a homeowner to handle, while other times you’ll need expert help to prevent further damage.

Why Does the Fan Turn Off but Compressor Stay On?

When your air conditioner’s fan stops spinning but you can still hear the compressor humming away, you’re experiencing a specific type of AC malfunction that needs attention. In a properly functioning system, these two components work together like dance partners – when one stops, the other should too. So what’s causing this uncoordinated performance?

A healthy AC system typically runs in cooling cycles lasting about 15-20 minutes, occurring 2-3 times per hour. When this rhythm gets disrupted and your fan turns off but compressor stays on, something’s definitely amiss.

Thermal Overload on Fan Motor

The most common culprit behind why your fan turns off but compressor stays on is the fan motor’s built-in thermal protection doing its job. This safety feature is like a vigilant guardian that shuts down the motor when it gets dangerously hot to prevent permanent damage.

“I can always tell when a customer has a thermal overload issue,” says Mike, one of our veteran technicians at Malek. “They describe their fan running for a while, shutting off mysteriously, then starting up again later – all while the compressor never misses a beat.”

This stop-and-go pattern happens because most fan motor overload sensors automatically reset themselves after cooling down. The motor might run for anywhere from 5 to 60 minutes, shut off when overheated, then restart once it’s cooled sufficiently.

What’s causing all this overheating? Often it’s worn bearings creating excessive friction, like trying to pedal a bicycle with rusty chain. Age-related wear on motor windings, dust buildup restricting airflow, and our brutal Texas summer heat can all contribute to the problem.

A decade-old fan motor that’s faithfully cooled your home through ten Texas summers has likely accumulated significant wear and tear. As components degrade, they create more resistance and generate more heat during operation – it’s like an aging runner who can’t complete a marathon without taking breaks.

For more information about preventing these issues with regular maintenance, visit our HVAC Maintenance page.

“fan turns off but compressor stays on” Due to Bad Capacitor

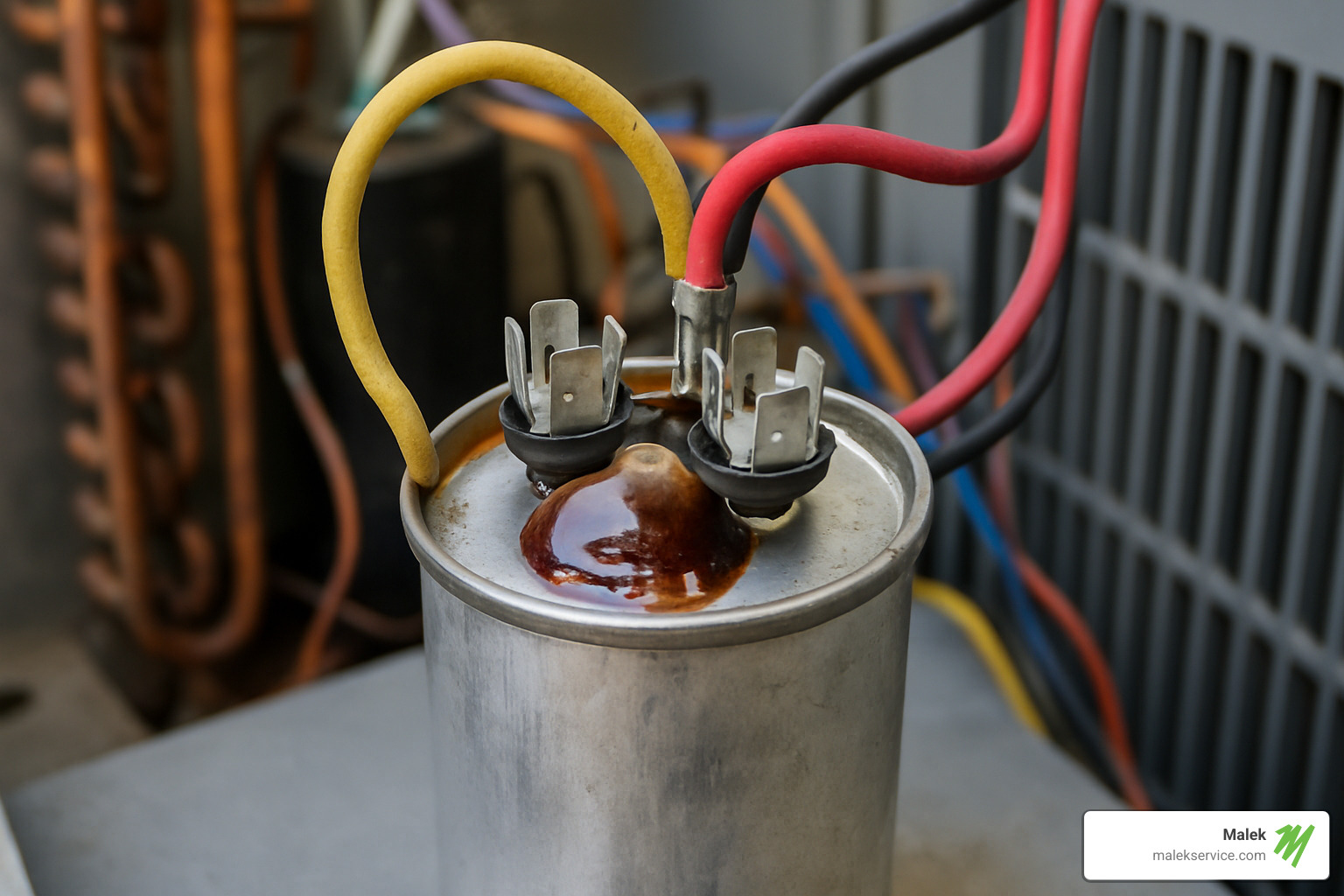

Did you know that failing capacitors account for about 60% of all single-phase motor failures in HVAC systems? That makes them one of the most frequent reasons your fan turns off but compressor stays on.

Think of a capacitor as your AC’s personal energy drink – it provides that initial jolt of electricity needed to start the fan motor and helps maintain smooth operation. When this component fails, your fan may not get enough power to start or stay running, while the compressor (which might have its own separate capacitor) continues working away.

You can often spot a failing capacitor by its physical appearance. A healthy capacitor should have a flat top, while a failing one might look like it’s been working out too much – sporting a bulged or domed top. You might also notice oily residue leaking from it, or hear your fan humming but not actually spinning.

Sarah in College Station recently told us: “I kept hearing my outdoor unit running, but my house was getting hotter by the minute. When your technician arrived, he immediately pointed to my bulged capacitor and replaced it in just minutes. Like magic, the fan started working and cool air returned!”

Capacitors are rated in microfarads (μF), and they lose capacity with age – like a phone battery that doesn’t hold a charge like it used to. Once a capacitor has lost more than 10% of its rated capacity, it won’t provide enough power to keep your fan motor running consistently.

Many modern AC systems use dual-run capacitors that serve both the fan and compressor. However, even with these two-in-one units, the fan section can fail while the compressor section soldiers on, leading to the situation where your fan turns off but compressor stays on.

The silver lining? Capacitor replacement is one of the most affordable AC repairs, typically running between $150-$400 depending on the type and size needed.

Stuck Contactor or Relay Problems

Electrical components called contactors and relays act as traffic cops directing power to your AC components. A contactor is essentially a heavy-duty switch – when it closes, power flows to your compressor and fan motor; when open, everything should stop.

A stuck contactor ranks among the top 5 most replaced AC components according to HVAC repair forums, and it’s frequently behind the mysterious case of the compressor that won’t stop running.

When a contactor gets stuck in the “closed” position, it’s like a light switch that’s jammed in the “on” position – continuously supplying power to the compressor regardless of whether your thermostat is asking for cooling. Meanwhile, if the fan relay or circuit has failed, your fan won’t get the memo to start spinning.

What causes these contactors to stick? Electrical arcing can literally weld the contacts together (imagine tiny lightning bolts fusing metal parts). In Texas, we also frequently see insect infiltration – particularly ants who seem magnetically attracted to electrical components. Dirt, debris, and normal wear and tear are other common culprits.

One memorable case in Houston involved a determined colony of ants that had built their home inside a contactor housing. The ants had created a living bridge across the electrical contacts, causing sporadic operation until eventually, the contacts welded together completely.

Our experienced Malek technicians have a systematic approach to diagnosing whether the problem is in the control circuit or the components themselves. “If the indoor blower has an issue, you know it’s in the furnace; if it runs properly, the problem is likely in the thermostat or wiring,” explains our senior technician Tom.

For systems that frequently struggle with contactor issues, installing a delay-on-make timer on the 24 VAC control line can prevent “contactor chatter” (rapid on-off cycling) and extend the life of these vital components, while also protecting against power surges that might damage your system.

Diagnosing the Problem Safely at Home

When you find your fan turns off but compressor stays on, there’s no need to panic. Before calling us at Malek, you can safely investigate a few things yourself. I’ve guided hundreds of homeowners through these simple checks over the phone, often resolving their issues without needing a service call.

Quick Checks Before You Call

Your thermostat is the command center of your cooling system, so start there. Make sure it’s actually set to “COOL” mode and not accidentally switched to “FAN” or “OFF.” I can’t tell you how many times I’ve arrived at a home only to find the thermostat was simply on the wrong setting! Also check that your temperature is set below the current room temperature, and that the fan switch is set to “AUTO” rather than “ON.” While you’re there, check if the display looks dim – weak batteries can cause strange behavior.

Next, take a peek at your air filter. A clogged filter is like trying to breathe through a pillow – your system struggles and overheats. I’ve seen filters so clogged they were causing the fan motor to shut down from overheating while the compressor kept chugging along. Most Texas homes need filter changes every 1-3 months, especially during our brutal summer months.

Circuit breakers are another common culprit. Sometimes only one breaker trips – often the one connected to your fan – while the compressor breaker remains on. This perfectly explains why your fan turns off but compressor stays on. Check your home’s electrical panel for any switches that aren’t fully in the “ON” position.

Don’t forget to check the outdoor disconnect box – that gray electrical box mounted near your outdoor unit. It needs to be fully in the “ON” position for proper operation. I once had a customer whose landscaper accidentally bumped this switch to the halfway position, causing intermittent fan operation.

Finally, give your outdoor unit a quick visual inspection. Look for obvious damage like burnt wires, melted plastic, or signs that critters have made your AC their new home. Texas fire ants love to nest in electrical components, and they’re a leading cause of AC failures during summer months.

For more troubleshooting help, our A/C Troubleshooting page has detailed guides with pictures.

Step-by-Step Test Flow for “fan turns off but compressor stays on”

If your initial checks don’t solve the mystery, let’s dig a little deeper with some safe diagnostic steps.

First, isolate the fan by setting your thermostat to “FAN ON” mode (not cooling). This bypasses the cooling cycle and directly commands the fan to run. If your fan works in this mode but not during cooling, you’re likely dealing with a control issue rather than a fan motor problem. If it doesn’t run in either mode, your fan motor or capacitor is probably the culprit.

When your fan turns off but compressor stays on, it’s helpful to check if the fan can move freely. Turn off power to the unit both at the breaker and the outdoor disconnect (safety first!), then try rotating the outdoor fan blade using a wooden stick or similar tool – never your fingers! The blade should spin smoothly with minimal resistance. If you feel grinding or significant resistance, the motor bearings may be failing.

With the power still off, you can safely remove the access panel to peek at the capacitor – that cylindrical component that looks a bit like a soda can. A healthy capacitor should have flat or slightly rounded ends. If you see bulging, leaking fluid, or discoloration, you’ve likely found your problem. Never touch the capacitor terminals as they can store an electrical charge even when the power is off!

While you have the panel open, take a look at the contactor too. This square-ish component with visible metal contacts is essentially the “switch” that turns your unit on and off. Check for obvious issues like burnt contacts, debris stuck between the contacts, or contacts that appear to be stuck together.

I always remind homeowners that while these checks are generally safe, HVAC systems combine high voltage electricity, pressurized refrigerant, and moving parts – a potentially dangerous mix. When in doubt, it’s better to call us professionals at Malek. We have specialized tools and training to safely diagnose and repair your system.

Speaking of tools, there’s quite a difference between what you might have in your toolbox versus what our techs carry:

| DIY Testing Tools | Professional HVAC Tools |

|---|---|

| Basic multimeter ($20-$50) | Advanced multimeter with capacitance testing ($100-$300) |

| Infrared thermometer ($20-$60) | Refrigerant gauges and manifold ($200-$500) |

| Screwdriver set ($15-$30) | Specialized HVAC tool kit ($500+) |

| Fin comb ($10-$15) | Recovery machine ($1,000+) |

| DIY air pressure gauge ($15-$25) | Digital psychrometer ($200-$300) |

These simple checks can help you understand what’s happening when your fan turns off but compressor stays on, potentially saving you time and money. But remember, if you’re uncomfortable performing any of these steps, our team at Malek is just a phone call away, ready to help restore your comfort safely and efficiently.

Risks of Letting the Compressor Run Without the Fan

When your fan turns off but compressor stays on, you’re facing more than just a lack of cooling. This condition creates several serious risks that can lead to expensive repairs or complete system failure if not addressed promptly.

Compressor Overheating and Damage

The condenser fan isn’t just an accessory—it’s a vital component that removes heat from the refrigerant. Imagine wearing a winter coat while running a marathon in Texas summer heat. That’s essentially what your compressor experiences when the fan stops working.

Without proper airflow across those condenser coils, refrigerant pressure can skyrocket, potentially exceeding 450 psi (the typical high-pressure cut-out threshold). Your compressor’s operating temperature climbs beyond safe limits, breaking down the lubricating oil that keeps everything running smoothly.

“Running for roughly an hour before shutting down suggests motor overheating or winding failure,” notes one of our senior technicians. This brutal cycle of overheating and cooling gradually degrades internal components until catastrophic failure occurs—much like repeatedly overheating your car’s engine would eventually lead to a breakdown.

The motor windings inside your compressor can short out from this excessive heat, while valves and seals warp or fail completely. What might have been a simple fan repair can quickly escalate to replacing your entire compressor—often the most expensive component in your AC system.

Refrigerant System Complications

Your air conditioner’s refrigerant system operates on a delicate balance that’s thrown completely off when the fan stops working.

Without proper heat removal, refrigerant may not properly condense, dramatically reducing system efficiency. A particularly dangerous condition called “flood-back” can occur, where liquid refrigerant returns to the compressor instead of vapor. This is like putting water in your car’s gas tank—it’s simply not designed to handle it.

This liquid refrigerant washes away oil from moving parts, causing accelerated wear on components that are designed to last for years. Meanwhile, thermal expansion stresses refrigerant lines and connections, often leading to leaks that require extensive repairs.

I recently visited a home in Bryan where the homeowner had ignored this issue for weeks. By the time we arrived, the compressor had suffered irreparable damage from oil breakdown, and refrigerant had leaked from a connection that had failed due to excessive pressure.

Energy Waste and Environmental Impact

Your utility bill will reflect this problem before you might even notice the lack of cooling. A system running with the fan turns off but compressor stays on consumes electricity without providing any meaningful cooling benefit.

The compressor runs much longer trying desperately to satisfy the thermostat setting—sometimes continuously—while operating at extremely poor efficiency. This not only increases your utility bills but also creates unnecessary carbon emissions from all that wasted energy.

One College Station customer told me their electricity bill doubled during the month their fan was intermittently failing. They assumed it was just the summer heat causing higher bills, not realizing their system was essentially running a marathon while breathing through a straw.

Impact on Indoor Comfort and Health

Beyond the mechanical concerns, there are real health implications when your cooling system isn’t functioning properly. Scientific research on heat stress published in the American Heart Association Journals highlights the health risks associated with inadequate cooling, particularly for vulnerable populations like the elderly, children, and those with chronic health conditions.

When your AC fan isn’t running, indoor humidity rises as moisture isn’t being removed from the air. Air circulation decreases, creating uncomfortable hot and cold spots throughout your home. Your system’s air filtration is reduced, potentially affecting indoor air quality at a time when you need it most.

These temperature fluctuations can stress your body’s temperature regulation systems, leading to discomfort and potentially more serious health concerns during extreme heat.

One customer in Brazos County shared a painful lesson: “I didn’t realize how serious it was when I heard the unit running but felt warm air. By the time I called Malek, my compressor had overheated multiple times and needed replacement. I wish I’d called at the first sign of trouble.”

Don’t let this happen to your system. When you notice your fan turns off but compressor stays on, consider it an urgent matter requiring immediate attention. Your comfort, health, and wallet will thank you.

When to Repair, Replace, or Upgrade Components

When your fan turns off but compressor stays on, you’re faced with an important decision: fix the individual parts or invest in larger system upgrades? Let’s walk through your options to help you make the choice that’s best for your home and wallet.

Replacing the Fan Motor vs. Other Parts

I’ve seen many homeowners struggle with this decision, especially when facing unexpected AC problems during the hottest Texas days. Here’s what you should consider:

A fan motor replacement makes the most sense when your system is relatively young (under 10 years) and otherwise healthy. If your compressor is running strong and the rest of your system looks good, replacing just the motor can save you thousands compared to a full system replacement.

One of our senior technicians at Malek often tells customers, “If your fan starts up but quickly shuts down, don’t assume it’s just the capacitor. While we’ll replace that inexpensive part as a precaution, we need to address what’s actually causing your motor to fail.”

When we replace a fan motor, we’re careful to match several critical specifications exactly. The horsepower (HP) and RPM ratings must be identical to your original motor for proper operation. We’ll also discuss whether an OEM motor (made by your system’s manufacturer) or a quality universal replacement makes more sense for your situation.

Looking at typical costs, here’s what you might expect:

– Replacing just the condenser fan motor typically runs $200-$700 installed

– A simple capacitor replacement costs $150-$400 installed

– Contactor replacement generally falls between $150-$350 installed

– A complete new condenser unit starts around $1,500-$4,000+ installed

– Full system replacement (indoor and outdoor units) ranges from $5,000-$12,000+

For systems older than 12 years, the math often favors replacement rather than repair, especially when dealing with major components. Modern systems can be 30-50% more efficient than units from just a decade ago, creating significant energy savings that help offset the investment over time.

“When I see a 14-year-old system with a failed motor,” says our comfort advisor James, “I always show customers both options. Sometimes the repair makes sense for their situation, but often they’re surprised by how much they can save long-term with a new energy-efficient system.”

For more details about your repair options, visit our HVAC Repair page.

Preventive Maintenance to Avoid Future “fan turns off but compressor stays on” Events

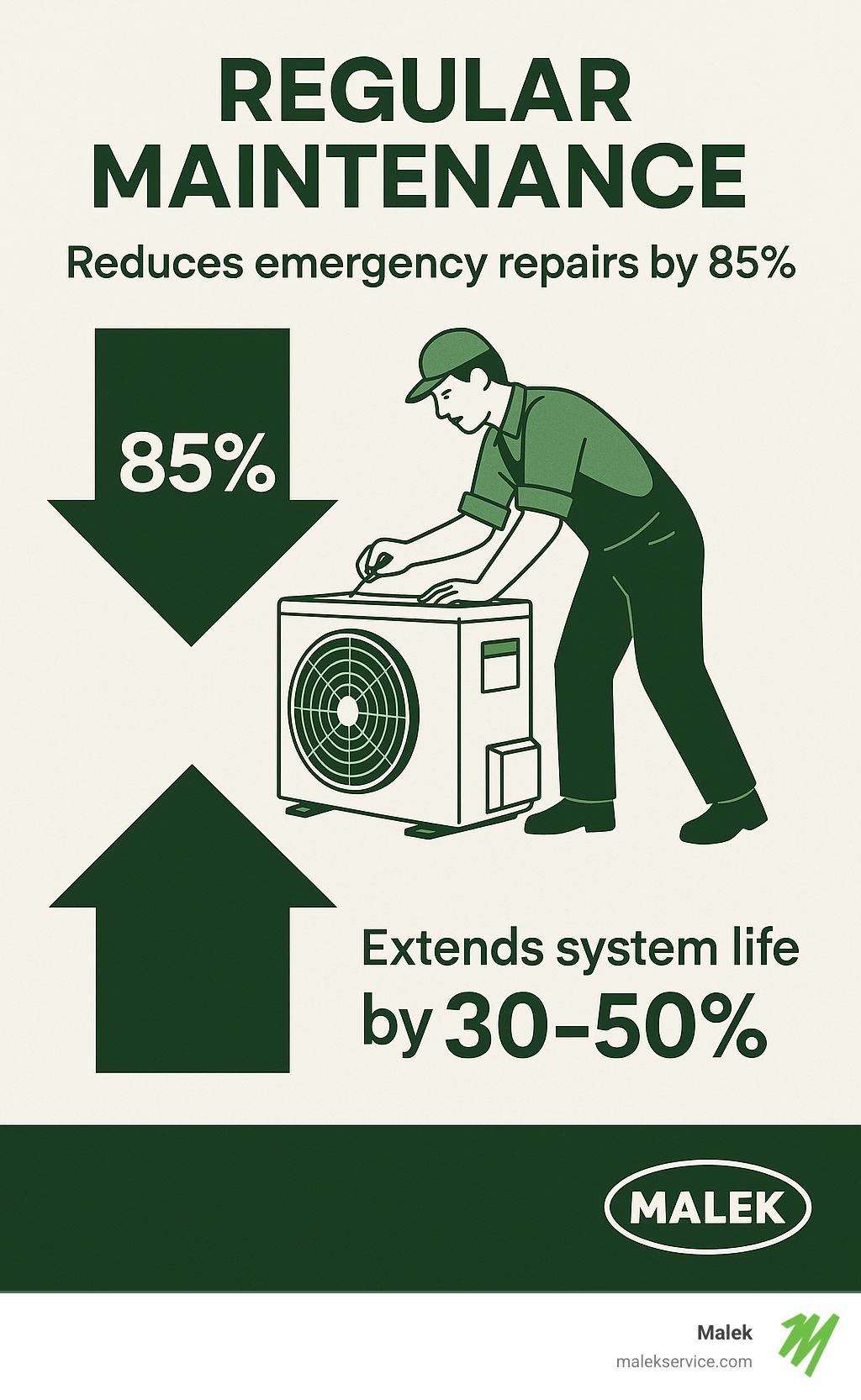

An ounce of prevention truly is worth a pound of cure when it comes to HVAC systems. At Malek Service, we’ve seen how regular maintenance prevents the exact scenario where your fan turns off but compressor stays on.

Our comprehensive maintenance program focuses on keeping all components in peak condition. We perform seasonal tune-ups before summer and winter, catching small issues before they become expensive emergencies. During these visits, our technicians thoroughly inspect electrical components, test capacitor performance, check contactor condition, and measure motor amperage draw to spot potential problems early.

Filter maintenance is something you can handle between our visits. Simply check your filter monthly and replace it every 1-3 months depending on your home’s conditions. Homes with pets, allergy sufferers, or in dusty areas need more frequent changes. This simple step dramatically improves airflow and reduces strain on your system.

Condenser coil cleaning is another crucial maintenance task we perform annually. Those outdoor coils collect dirt, debris, and even cottonwood fluff that can severely restrict airflow. “Clean coils are happy coils,” as our lead technician often says. “When they can breathe freely, your system runs cooler, more efficiently, and lasts years longer.”

We also pay special attention to lubrication of moving parts during maintenance visits. Those fan motor bearings, blower motor bearings, and other mechanical components need proper lubrication to reduce friction and heat—two primary causes of motor failure.

“The most common fan failures we see could have been prevented with basic maintenance,” shares our service manager. “Clean filters and coils alone eliminate a huge percentage of the emergency calls we receive during summer heat waves.”

Our customers who participate in our regular maintenance program experience 85% fewer emergency repairs and enjoy systems that last 30-50% longer than those without maintenance. That’s real peace of mind and significant savings over the life of your system.

For more details about our comprehensive maintenance approach, visit our AC Maintenance Services page and find how we can help protect your comfort and equipment.

Frequently Asked Questions about Fan & Compressor Issues

Can I keep running the AC if the fan shuts off?

No, you should not continue to run your AC if the fan shuts off but the compressor stays on. I can’t stress this enough – continuing to run your system in this condition is like driving a car with an overheating engine. You’re headed for trouble!

When your fan turns off but compressor stays on, your system faces several serious risks. Your compressor will likely overheat without proper airflow to remove heat. You’ll also be paying for electricity without getting any cooling benefit, which is literally throwing money out the window. Worse yet, the refrigerant system can sustain damage that might lead to a complete system failure.

One of our customers learned this lesson the hard way last summer when they ignored the symptoms for several days. What could have been a simple capacitor replacement turned into a full compressor replacement costing thousands. As our senior technician often says, “Running an AC with the fan off but compressor on is like running a car with a failed radiator fan—you’re headed for engine failure.”

If you notice this happening, please turn your system off at the thermostat and give us a call right away. Your wallet (and your comfort) will thank you!

How do I know if the capacitor or motor is bad?

Figuring out whether you’re dealing with a bad capacitor or a bad motor requires a bit of detective work. Here’s how to tell the difference:

When your capacitor is failing, you might notice that your fan hums but doesn’t start spinning. Sometimes, if you give the fan a gentle push with a wooden stick (never use your hand!), it might start running. The fan might also run briefly before stopping again. If you can see the capacitor, look for visible bulging or leaking, which are clear signs of failure. You might also hear repeated clicking sounds as the system tries unsuccessfully to start.

A bad motor, on the other hand, often announces itself with unpleasant grinding or squealing noises while running. After turning off power, you might notice the motor housing feels extremely hot to touch. If you try to manually turn the shaft (with power off), you’ll feel excessive play or resistance. The motor might also run for a while before stopping, then restart after cooling down, creating a frustrating cycle. Sometimes, you’ll even catch a burning smell during operation.

“If the fan can start and run briefly, a bad capacitor is unlikely the primary fault,” one of our HVAC professionals explains. That said, since capacitors are relatively inexpensive, we often replace them as a preventative measure even when diagnosing a motor problem – it’s good insurance against future issues.

How often should I schedule maintenance to prevent this problem?

Regular maintenance is your best defense against the fan turns off but compressor stays on scenario. Think of it as health check-ups for your AC system – much cheaper than emergency surgery!

For Texas homeowners, we recommend bi-annual professional maintenance visits. Schedule one in spring before cooling season hits (which, let’s be honest, comes early and stays late in our part of the country) and another in fall before heating season. These visits allow us to catch small issues before they become big problems.

Between professional visits, there’s plenty you can do yourself. Check your filter monthly and replace it when it looks dirty – this simple habit prevents many system failures. Every few months, take a moment to clear debris, leaves, and vegetation from around your outdoor unit. Once a year, have the electrical components inspected to catch weakening capacitors, worn contactors, and loose wiring connections before they fail.

As our service team likes to say, “Regular maintenance will solve most compressor problems and prevent future failures.” This is especially true in our Texas climate, where extreme heat puts extra strain on AC systems. Our technicians in College Station, Houston, and surrounding areas understand these unique challenges and can help keep your system running smoothly all summer long.

Preventive maintenance is always less expensive than emergency repairs or system replacement. It’s the difference between a small tune-up bill and facing a sweltering Texas summer with no air conditioning!

Conclusion

When your fan turns off but compressor stays on, you’re dealing with more than just an uncomfortable home. This common issue puts your entire cooling system at risk while driving up your energy bills. Whether it’s a simple capacitor failure, electrical problem, or motor burnout, addressing the problem quickly is essential.

Here at Malek Service, we see this situation all too often across College Station, Houston, and surrounding Texas communities. Our technicians have become experts at quickly diagnosing these issues because, let’s face it, nobody wants to be without proper cooling during our scorching Texas summers!

I remember one customer in College Station who ignored the early warning signs – that distinctive sound of the compressor running without the fan. By the time they called us, their compressor had overheated repeatedly and needed complete replacement. What could have been a simple $200 repair turned into a $2,000 ordeal.

This is why we always emphasize these important points:

1. Never keep running your system if you notice the fan isn’t working

2. Simple regular maintenance like changing filters and cleaning coils prevents most problems

3. Professional tune-ups twice yearly provide the best protection against unexpected failures

4. Addressing small issues early saves you significant money and headaches later

Our approach is straightforward – thorough diagnostics, honest recommendations, and quality repairs using the best parts available. We don’t believe in band-aid solutions that leave you vulnerable to recurring problems. Whether you need a quick capacitor swap or a comprehensive system evaluation, our team has the expertise to get your cooling back on track.

Texas summers are challenging enough without AC troubles. Don’t let a failing fan escalate into a failed compressor and an uncomfortably hot home. Contact Malek Service today to schedule your AC Maintenance Services and ensure your system keeps running efficiently year after year.

After all, prevention is always more affordable than emergency repairs – and much more comfortable too!